When buying a sophisticated die-cutter, itis important to ensure it is giving you everything it possibly can. This iswhere tooling comes in. To ensure a constant production performance, convertersneed high-quality, premium tools. Without high-quality tools, converters maysee significant production losses. We recognize the need for optimal cutting,stripping and blanking tools to ensure process optimization. We appreciate theskill and craft of die-making and have created an industry-leading range oftooling solutions and expertise that enables die-makers to respond to theircustomers’ challenges.

BOBST is well known for its range ofAutoplaten® die-cutters. But in the last few years, we have also recognized thegrowing importance of optimized tooling. In 2017, we completed the acquisitionof Boxplan, offering many die-making innovations including the Hybridsetter,the ultimate equipment for production of dynamic stripping forms fordie-cutters. In addition, we recently announced a crucial partnership withCITO-System, which will leverage the strengths of both companies to driveinnovation in tooling and in packaging production.

“While we will continue to innovate, weknow we can’t find all the solutions at a central level. Tooling is and alwayswill be a very local craft, specific to die-makers and converters on theground,” said Alex Volery, Head of the tooling division at BOBST. “That is whywe made the decision in 2018 to run a Certification Program to supportdie-makers at a local level. The goal of the certification is to supportdie-makers to deliver the best possible tooling for BOBST machines. Highquality tools reduce setup times for the user to the absolute minimum, toincrease production speeds, keep the quality level constant for the whole orderand to extend tooling life as much as possible.”

BOBST Die-makerCertification Signing Ceremony

So far, 15 die-makers worldwide arebenefitting from this advantage, having completed the Certification Program. InChina,Wohing Laser Mould officially completed the Certification Program on 26th May.

Competence Center in Wohing plays avery important role in the partnership between Bobst Shanghai &Wohing,whether it is for BOBST sales &services ,or for the product proofing and R&D needs fromclinet,as well as the upgrade & improvement of BOBST machines

"We are happy to announce that Wohingcompleted the Die-maker Certification Program. After 35 years of development,the capability of Wohing in processing equipment, R&D and product qualityis well-known to all," said Ricky Zhao, Head of Bobst Service CenterGreater China. “Our tooling expertise – both in the innovations we develop andthe support and partnership we offer – can provide die-makers and converterswith a significant competitive advantage."

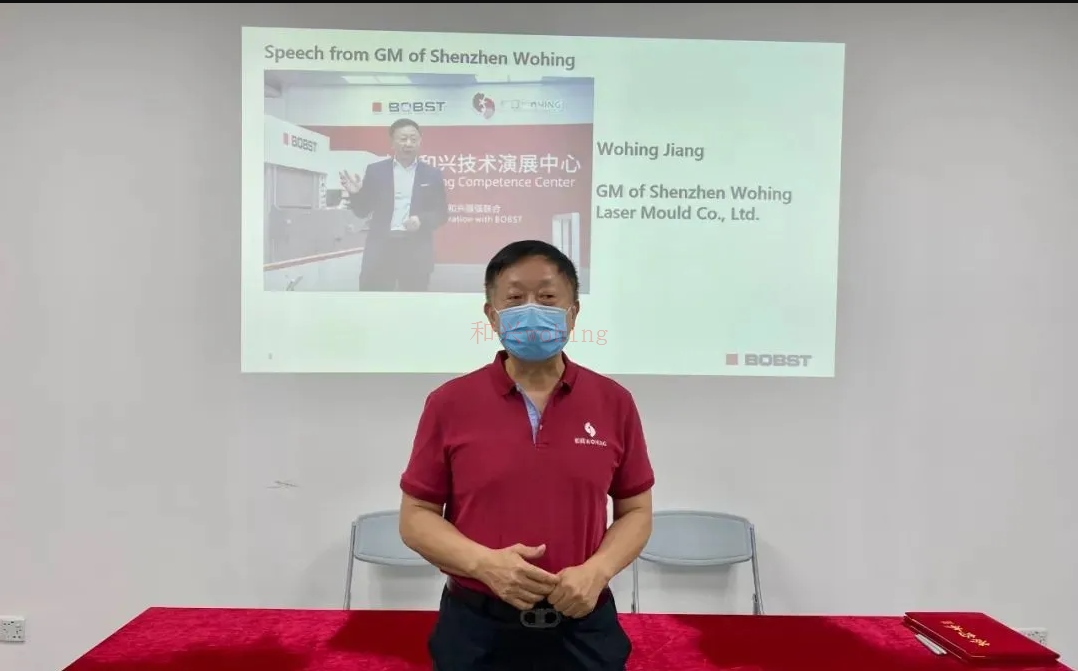

Wohing Jiang, the General Managerof Shenzhen Wohing

Wohing Jiang, the General Manager ofWohing, was also very excited about this: "For us, this is a kind ofrecognition and motivation. We will continue to optimize ourselves tocoordinate with the Bobst China 4.0 strategy, and hope we will get better andbetter with the cooperation of BOBST."

"In March 2018, BobstChinalaunchedits 4.0 strategy, committing to deliver tailored solutions for the dynamic andcompetitive Chinese market. Built on ‘Proximity’ and ‘Performance’, thestrategy has been developed to ensure customers are guaranteed the best inSwiss-quality technology with local production and local customersupport. Wohing now is joining the Certification Program, which is a veryimportant part of this strategy," said Mr. Cyril Ruiz-Moise, the GeneralManager of Bobst Shanghai.

Cyril Ruiz-Moise, the GeneralManager of Bobst Shanghai

“Ultimately, tool manufacturing – like thepackaging industry in general – will move towards more automation, digitalizationand connection. We feel that now we have everything in place to be able tofulfil this need. With our own tooling expertise and our partnerships withpioneers like Wohing, we will support the innovation and development of futuretooling solutions, and develop the best components in order for die-makers tomanufacture the best tooling for our machines and standardize components inthis fragmented industry.”

Wechat

Wechat Mobile Code

Mobile Code